One thing that has certainly changed over time is the type of posts used for mounting signs along the right-of-way. Originally starting as cast iron posts by the Richmond & Danville, the formation of the Southern Railway brought about wooden signs, multiple variations of cast iron, and eventually galvanized steel U-Channel that still has a modern variation in use to this day.

Richmond & Danville Cast Iron

The Richmond & Danville can easily be credited as the original designers of what would remain the “Southern Standard” until the end of cast iron. While almost all of their signs were one piece, the designs and standards would be repurposed by the Southern after its formation. The biggest difference between the R&D and later Southern standards was the cast number prefix. ALL Richmond & Danville signs used an “E” prefix while the Southern used an “R” prefix. This can be seen in some of the pictures below.

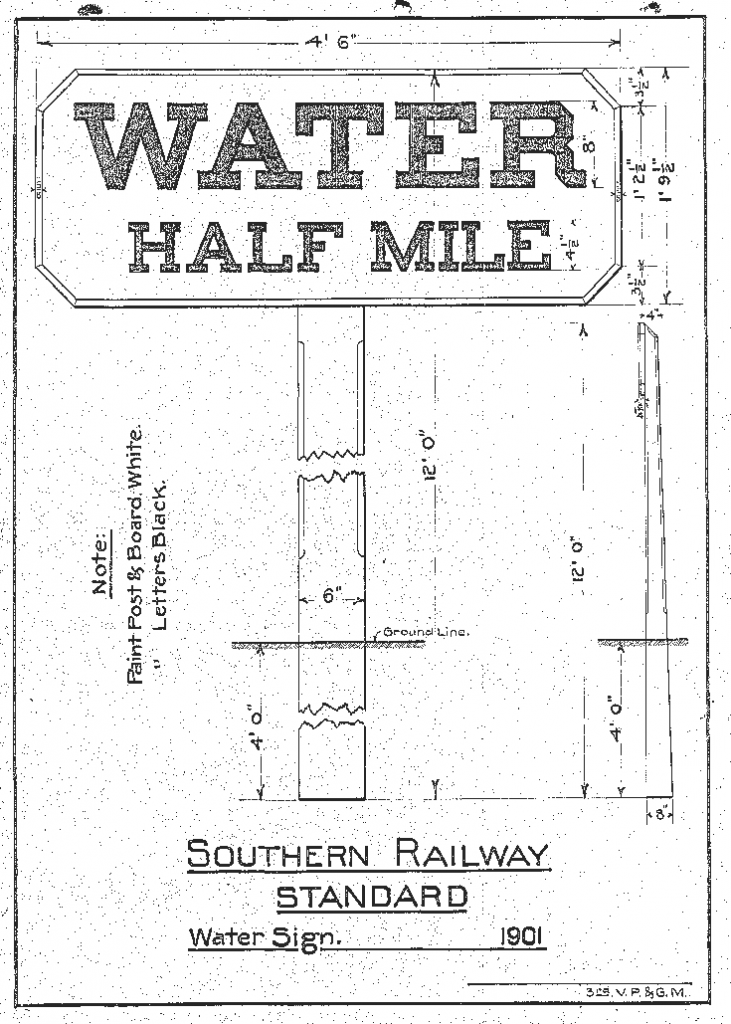

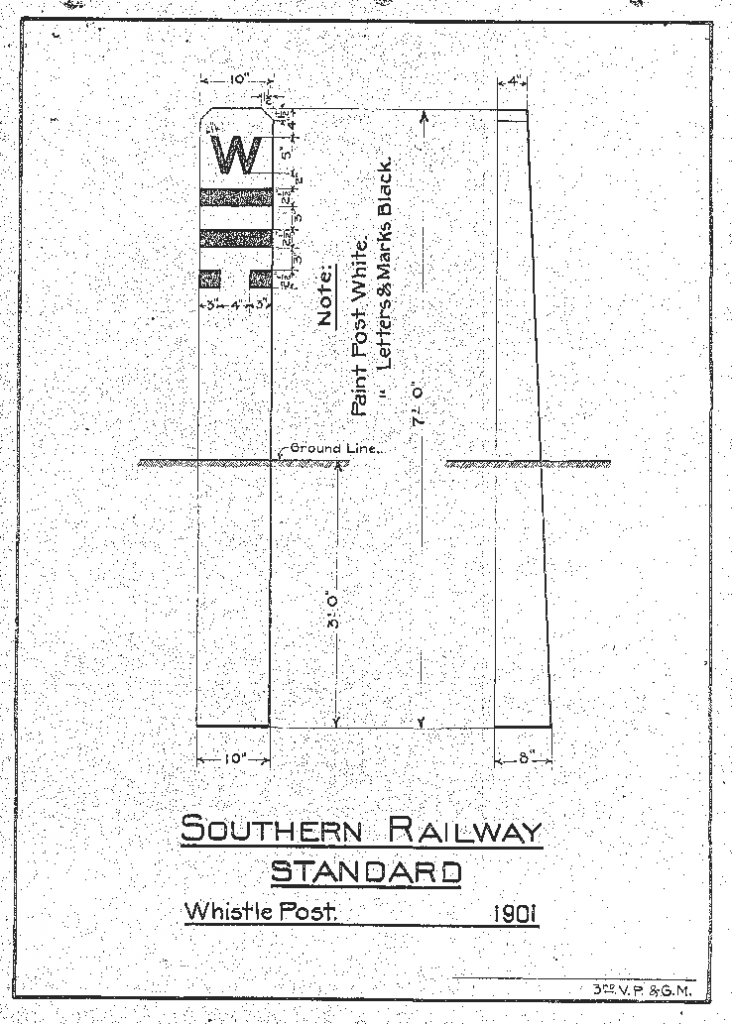

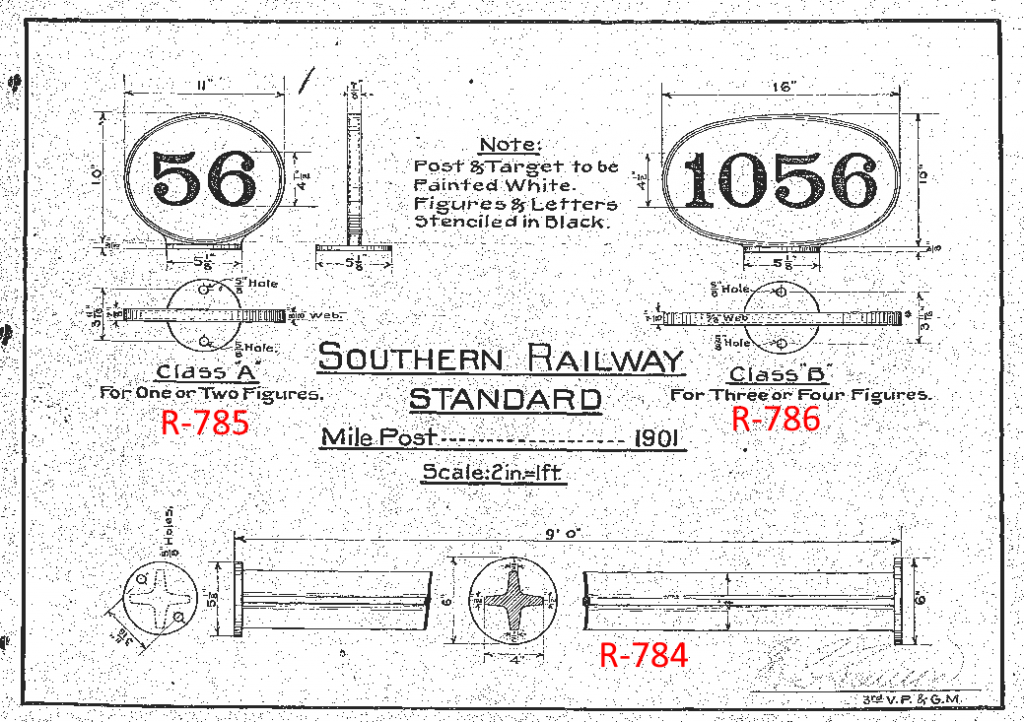

Early Southern Railway Wood and Cast Iron

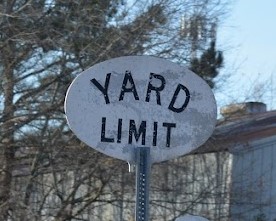

With the formation of the Southern Railway, lot’s of cost cutting measures were implemented to increase the efficiency of the new company. One of these was the creation of new wooden sign standards. The signs were used from the formation in 1894 to some time in the early 1910s throughout the Southern Railway system as needed. The term “post” doesn’t quite apply to any signs outside of the mileposts, which still used a similar design to the R&D standards, save for the individually cast numbers. There are no known surviving wooden signs today, as there were likely very few made and the signs would not have easily survived over the years in the elements.

Late Southern Railway Cast Iron

In the mid 1910s, new cast iron standards were put in place for the Southern Railway. These standards featured only 2 posts for use on ALL signs, and were used until the transition to aluminum signage in the 1960s. The two posts were a 9′ tall R-471 post and a 6′ tall R-476 post. The R-476 post was exclusively used for spring switch signs while the R-471 post was used for practically everything else. At some unknown point between the 1940s and 1960s, a 4-hole version of the whistlepost was standardized. This left the clearance post as the only remaining one-piece sign until the end of cast iron.

For installations with mileposts, the R-471 post would actually be turned to an “X” shape to allow standard milepost mounting with front and rear holes. By transitioning to these two posts for all signage, it greatly simplified the casting process allowing for hundreds to thousands of these posts to be made at the same time, then distributed as needed for any installation.

Unique Posts / Signs

Even with a standard post in place to allow for ease of casting, there were still a few outliers that remained. They were the whistlepost, clearance post, and railroad crossing warning post. The whistlepost and clearance post were both unique due to their one-piece casting, but the railroad crossing warning post was the ONLY post on the southern cast iron standards that had the sign mount to the front of the post rather than the top.

Capped Cast Iron

With the transition to aluminum signage, hardware had to be developed that allowed 1-piece cast iron signs to be reused as posts. The hardware that was used in the end was a “cap” that would be installed on top of the plus-post after the sign target had been removed by cutting or breaking the base.

Southern Railway Galvanized Steel

In the early days of the aluminum signage, as posts were replaced, a newer galvanized steel post started appearing in place of the cast iron posts. Since the Southern was still using the mounting brackets, the new posts featured a square 5⅛” x 5⅛” plate welded on top. The newer post was very simple, being constructed from a 3″ pipe, a plate, and two blades at the base to prevent rotation. While they were still just as long as the cast iron posts at 9 feet, these newer posts were significantly lighter and did not break easily compared to cast iron.

Southern Railway U-Channel

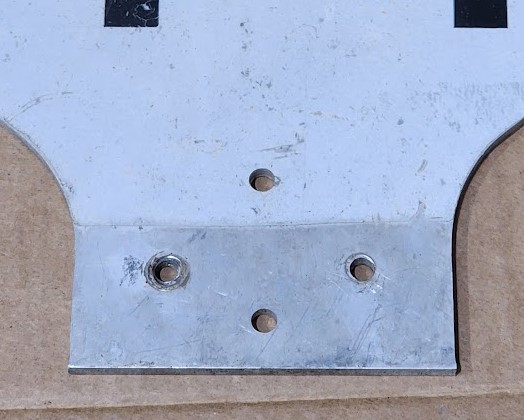

Eventually, a transition was made to a more modern, but still unique, steel u-channel. Unlike the u-channel used on roads and for other signage, the Southern’s u-channel featured only two holes along the back of the post, and an extra two holes in the lips of the post that matched up with the mounting holes on the aluminum signage. I can’t say for certain if this was always planned or just dumb luck, but it is incredible how well the holes matched. This allowed the signs to be made with the same dimensions as always, but still remain compatible with the cast iron posts remaining on the system.

Modern U-Channel

Towards the end of the Southern, and in the very early years of Norfolk Southern, modern galvanized u-channel began to appear along the right-of-ways. Multiple difference mounting methods were used, and this actually led to the drilling of 2 additional vertical holes on all Southern signage to allow for easier mounting to u-channel.